From Design to Die

Design

The coin minting process has remained largely unchanged since the early days of hand hammered coins, however these days with the advance of technology and manufacturing techniques, the coin minting process is much more precise allowing for greater clarity in the design, better quality and larger volume capabilities.

The first stage of creating a bespoke coin or medal design starts with research. From reading books, scrolling through internet pages or visiting museums the research stage of your project is key to understanding the theme being discussed. By capturing the key symbols, meanings and imagery that convey the meaning and emotion behind the theme, the coin design can quickly start formulating. Initially with thumbnail sketches leading to more elaborate sketches and then onto 3D design work we have the ability to create coin ready artwork that really gives you a taste of the final product.

Sculpting

The origins of Tower Mint come from sculpting with Raphael having trained as a sculptor. His work has captured the portraits of the rich and famous including H.M. Queen Elizabeth II, Michael Parkinson and Richard Attenborough to name but a few… so we like to think we know a thing or two about sculpting.

From approval of design we instruct a team of in-house sculptors to create bas-relief models offering a 3D glimpse of the final design. Plasters are traditionally carved between 25 – 35cm allowing every possible detail to be encapsulated perfectly so that when the model is scaled down to the diameter of the coin the design looks sharp and as close to reality as possible.

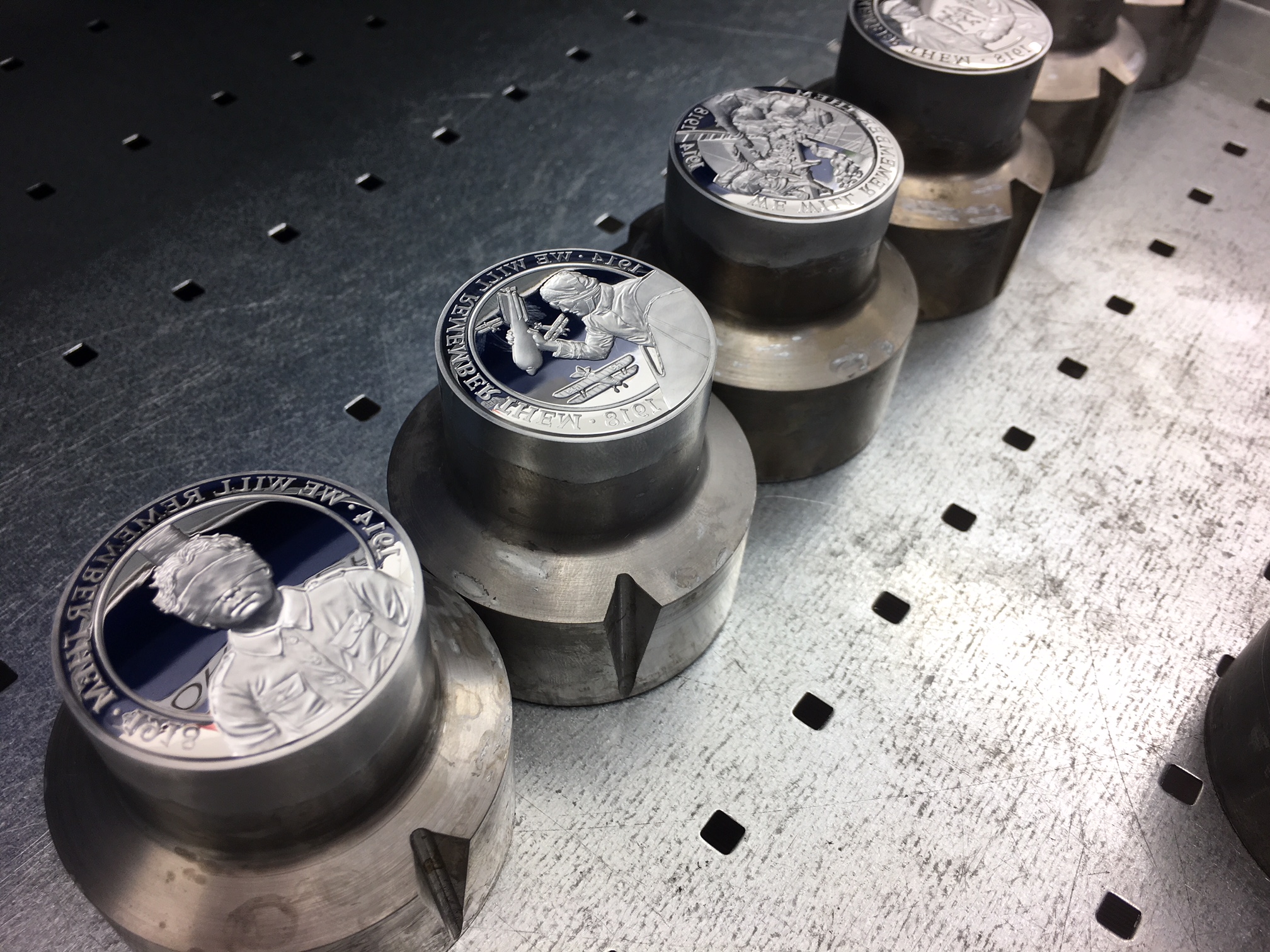

DIE CREATION

Specially designed engraving machines carry out the reducing process replicating every stroke of the sculptors model into a steel die as a negative impression. The steel dies are then hardened to ensure life cycles of tooling can be maximised.

Once the die has been hardened our die preparation team polish the die selecting areas of the table for mirror finish and frosting, once this process is complete the die is handed over to the minting team to initiate the minting process.

Minting

The minting process is a very precise art requiring exacting tolerance requirements on dies, collars and press tonnage to ensure a coin is struck to the upmost quality. Too much pressure and the dies and collars could crack and too little pressure would see little to no design visible on the coin.

Our expert team of press operators have a combined experience of over 200 years together having struck millions of coins so they will ensure your project meets with the highest standards and quality possible.

FINISHING

Once the minting process is complete we can offer a wide range of services in coin finishing techniques.

These services include full submersion plating, spot plating, selective colouring, numbering and assay marking. This wide range of bespoke finishing techniques allows you complete flexibility providing an entirely personalised final product.

QUALITY CONTROL & DELIVERY

Once your coin or medal is struck and finishing techniques have been applied it goes through a rigorous quality control process. Our team of eagle eyed QC operatives inspect your coin for any imperfections or areas that don’t meet our exacting standards. Any coins deemed unsuitable for approval are returned to the production department for re-processing.

Following QC approval the coin or medal is then ready for packing. With a range of packaging options from bespoke boxes, transport capsules and uniquely printed blister packs we can manage the full product development of your project. Once the product is packed and signed off for dispatch your product will be shipped by one of out trusted couriers right to your door.